I have been searching for one of the best boiler manufacturer for a long time. Through an online search, I came across Leo boiler. I was taken aback by their assistance and effective approach to everything. Highly recommend it!

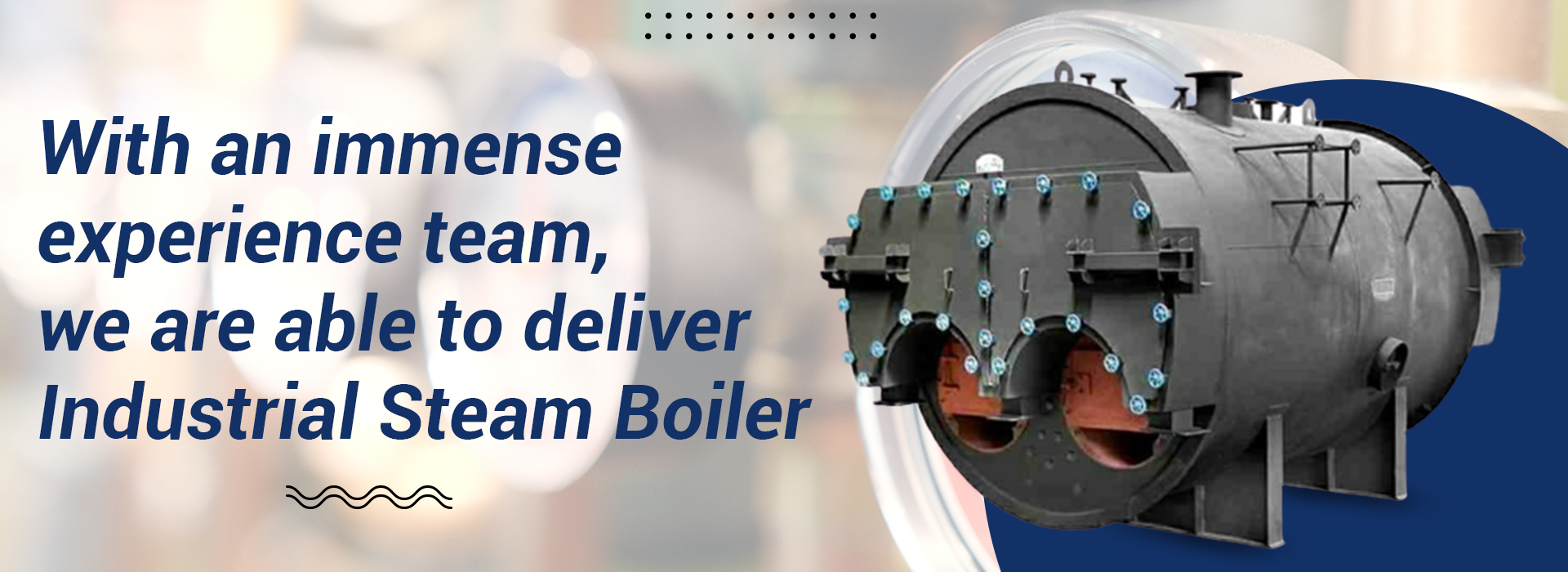

Leo Boiler is a reputed name in the field of industrial and steam boiler manufacturing since 2004. Based in Yamunanagar, Haryana, we specialize in designing, manufacturing, and supplying high-performance boilers across India. Our boilers are known for their durability, advanced technology, and energy efficiency, ensuring the best performance for every industry. The integrity and soundness of the entire team are vital to serving the clients with the finest quality products. It takes a huge responsibility to be one of the most trusted Boiler Manufacturers Haryana, India. And that you can see through the wide range of products we offer based on modern industry standards like Steam boiler, water tank, pressure vessel, water softening tank, jacketed vessel, Wet scrubber, dust collector, hot air generator, and much more. It’s time to seek the service that depicts perfection with everything.

A steam boiler is one of the most commonly used heating systems for steam production. Our professional team of boiler supplier in Haryana delivers the product that stands apart in terms of delivering quality results every time.

Thermic fluid heaters have stood the test of time as they offer several benefits like effectiveness, no pressurization, versatility, and minimal maintenance. Leo Boiler is one stop destination to seek this amazing product.

Hot air generators are for heating purposes required for any premises. Effective and fast working is the reason to drive the entire approach with perfection. Moreover, it requires less heating time as compared to others.

The water tank is another pivotal product that’s the basis of the boiler industry. Leo boiler manufacture and supplies premium quality water tank to fulfill all the demands of the clients. It’s time to trust Leo Boiler for the requirements.

For the premises to be dirt, dust, gases, and chemical free, the Leo Boiler product range dust collector offers the robust functioning you are looking for. The dynamic product and economical service await you.

Condenser stands out to lower temperature to make it easier for conversion into liquid form. As a boiler manufacturer we are giving the finest and optimally made condenser for serving the customer’s demand,

To be a leading name in the boiler industry, we have given our services to a wide range of customers to fulfill the requirements with the right approach.

Our esteemed client base is why we are always motivated to put the best foot forward. Our ethical business dealing and complete transparency are the reason for blooming trust with our reputed clients.

I have been searching for one of the best boiler manufacturer for a long time. Through an online search, I came across Leo boiler. I was taken aback by their assistance and effective approach to everything. Highly recommend it!

Thanks to Leo Boiler for supplying the necessary product on time. From the most affordable service to complete transparency, Leo Boiler is one of the best boiler manufacturer names in the industry.

When Leo Boiler is there, then there’s no need to worry. I have been in touch with them for 7 years for all the boiler manufacturing needs. Their working approach and availability of products always get me towards them. Thanks to the entire team.

Well, steam boilers are used to increase the temperature of a room or warehouse. And it is pretty essential to follow all necessary rules for proper inspection, and that can…

Read MoreSteam boilers – Uplifting the working process of the textile industry Steam boilers have widespread uses, one of which is with the textile industry for different purposes. The steam boilers…

Read MoreAvailability of different industrial hot boiler system Industrial hot water boilers are available in different types with various features and approaches to make temperature manageable. The assistance offered by the…

Read More